Description

The Feather Banner’s large space and ability to hold vibrant colours will make your design stand out; and will draw attention from the movement of the banner in the breeze.

The Feather Banner’s large space and ability to hold vibrant colours will make your design stand out; and will draw attention from the movement of the banner in the breeze.

The Feather Banner’s design is versatile and suits a multitude of logos, messages and applications, and is one of our best sellers. The shape of the Feather Banner allows for a generous branding area and is suitable for almost any design and will easily accommodate any large message or brand.

Now available printed onto Yellow or Orange Fluorescent Fabric.

Standard Package includes:

Printed Banner, Fibreglass Rods, Padded Carry Bag and Soft Ground Stake.

A variety of alternative base options are available to suit your mounting surface (Click here to see more)

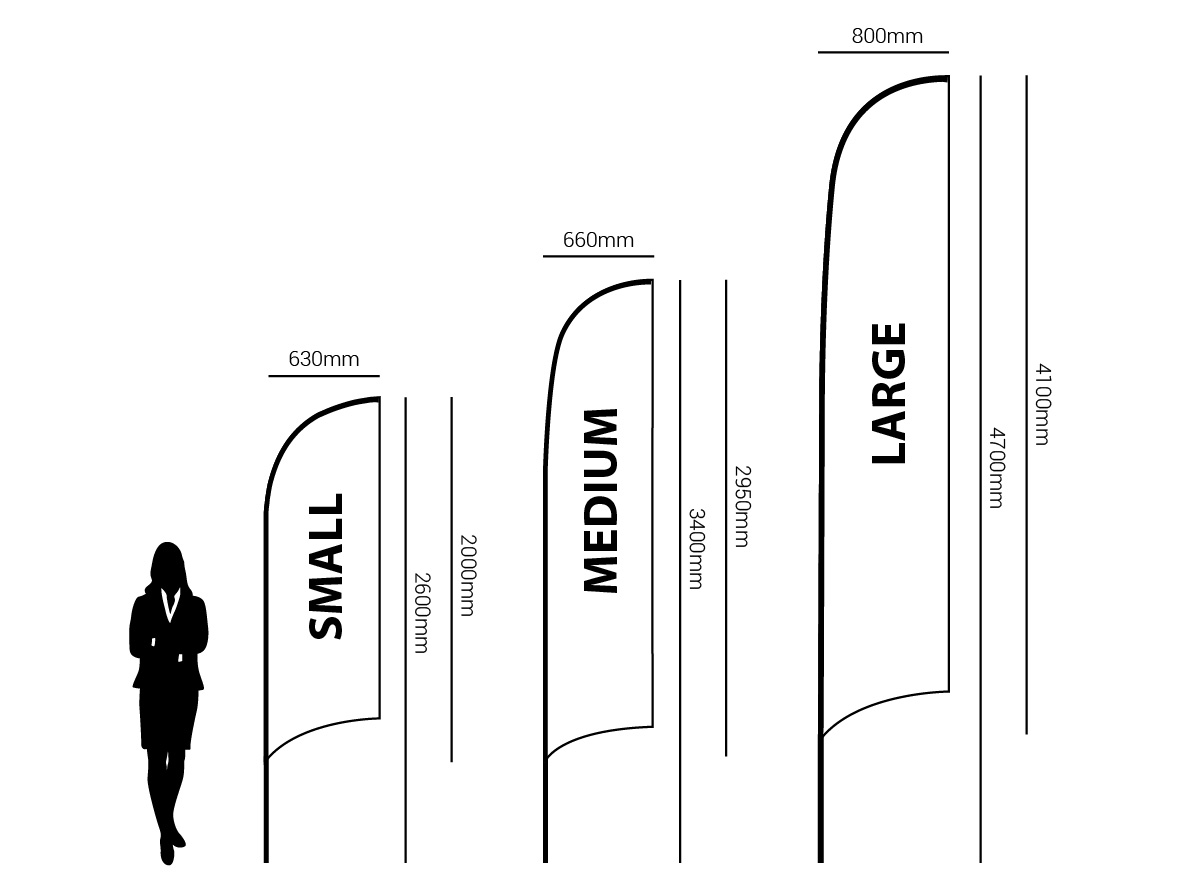

- Available in three sizes – Small, Medium and Large

- Full Colour Digital Printing

- Single or True Double-Sided Printing

- Replacement fabric skins are readily available

- Strong Fibreglass rods with Metal reinforcing

- Lifetime Guarantee on the Tip Rod

- Premium carry bag, with sections for the ground spike, and rods

- Easy to transport, assemble & take down